RESEARCHIntroduction

It has been more than 100 years since the polymer theory was first published, and in recent years we have seen many synthetic plastic products derived from petroleum. Plastic products have dramatically improved our quality of life by providing functions that are not available with conventional metals, stone, glass, or natural materials. However, since petroleum (crude oil) reserves are limited and it is a precious natural resource that is indispensable to our daily lives, it is important to reduce the use of petroleum resources and increase our dependence on other natural resources in order to make our lives more comfortable and to use them longer.

In the Functional Materials Laboratory, we are mainly engaged in the evaluation of polymer degradation, plastic film bonding, traditional craft materials, and natural fiber composites. Research on extending the service life of polymeric materials, using natural materials, and reducing the environmental impact of waste plastic materials through recycling are also important. Furthermore, the development of environmentally friendly plastic film materials for packaging and sealing technology is another important issue.

For the development of new materials and the enhancement of functionality, basic polymer material science is necessary to enable structural control and quantitative evaluation of polymer materials. Our research is based on "nanostructure control" and "evaluation of physical properties," and has attracted the attention of many companies from the viewpoint of functional material development and long-term durability. Our research results have been published in numerous papers and patents. The results obtained in our laboratory will contribute not only to the development of polymer materials science but also to new technologies.

01

Evaluation of polymer degradation

Petrochemical-derived plastic (polymer) materials are used in a great many products as a substitute for metal and wood because they are inexpensive, easy to mold, and lightweight. However, from the viewpoints of environmental load reduction and petroleum resource issues, it is important to reduce the production, use, and disposal of plastic products as much as possible and to keep plastic products in use for a long time. On the other hand, it is known that many polymer materials easily deteriorate when exposed to environmental effects such as light, heat, and water. Therefore, our laboratory has conducted research on long-term durability evaluation of plastic materials by exposing plastic molded products to harsh environments such as high temperature, high humidity, and UV irradiation, which accelerate degradation.

Recently, we have also succeeded in capturing the structural changes of plastic materials before and after degradation in a non-destructive and non-contact manner by making full use of fluorescence spectroscopy and other spectroscopic methods. In the future, we aim to develop a more convenient measurement technique.

【Related Papers】

1."Development of Glossy and UV-Resistant Urushi Coatings by Thermal Polymerization", Chieko Narita, Kazushi Yamada*, Progress in Organic Coatings, 186 (2024) 108032. (https://doi.org/10.1016/j.porgcoat.2023.108032)

2."Effect of surface treatment of cotton fibers on the durability of polylactic acid/cotton-fiber biocomposites", Linmei Zhang, Jiaru Zhou, Hiroki Sakamoto, Kazushi Yamada*, Advanced Composite Materials (2022) 2055515. (https://doi.org/10.1080/09243046.2022.2055515)

3."Influence of residual chlorine and pressure on the degradation of water pipes of polyethylene of raised temperature", Takehiro Fujii, Hideo Hirabayashi, Yuichi Matsui, Kazushisa Igawa, Hidekazu Honma, and Kazushi Yamada*, Polymer Degradation and Stability, 194 (2021) 109760. (https://doi.org/10.1016/j.polymdegradstab.2021.109760)

Please see other related papers Click.

02

Heat Sealing of Polymer Films

The packaging for snacks, retort pouch foods, and other food products that we usually buy or eat without much thought are made by laminating films together using the heat sealing method. Plastic bags and paper cups are also sealed or laminated. Since these have penetrated deep into our daily lives and have become very convenient product technologies, the amount of plastic film packaging can be reduced, but not eliminated, in the future.

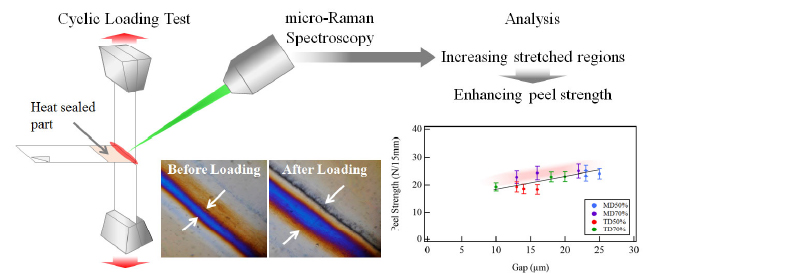

Our laboratory is conducting research on impulse sealing and laser welding methods to improve low-temperature sealing and sealing performance of plastic films. Only a few laboratories in Japan are conducting academic research on sealing plastic films for packaging. By establishing low-temperature sealing technology, we aim to contribute to energy usage and cost reduction in plastic film packaging.

【Related Papers】

1."No-Surface-Damage Laser Welding of Fluoroplastic Sheets: Welding of PFA and PTFE Sheets", Kimitoshi Sato, Kazushi Yamada, Vol.35 No.2, Seikei-Kakou (2023), pp.63-70. https://doi.org/10.4325/seikeikakou.35.63

2."A novel methodology for peel strength enhancement of heat-sealed oriented polypropylene/cast polypropylene film by tensile cyclic loading", Kazushi Yamada*, Ken Miyata, and Ramanujam Kumaresan, Materials Chemistry and Physics, Vol.187, pp.112-118, 2017. (http://dx.doi.org/10.1016/j.matchemphys.2016.11.054)

Please see other related papers Click.

03

Traditional craft materials and natural fiber composite materials

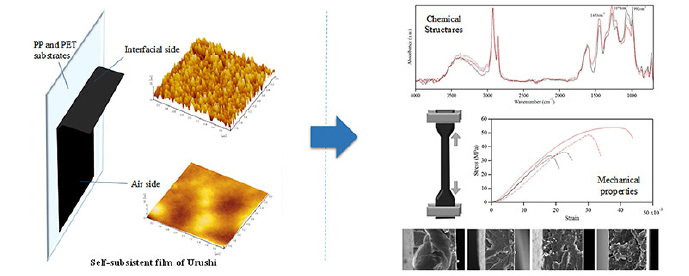

Biodegradable plastics and biomass plastics in particular have been attracting attention recently. Prof. Yamada has been observing the nanostructure of silk fibroin molecular chains using an atomic force microscope since he was a student in the Department of Macromolecules in the Faculty of Textile Science and Technology, and he is using this expertise to conduct collaborative research on the creation of silk fibroin nanofibers by the grinder method. We have also conducted numerous studies using lacquer and Japanese paper, which are traditional craft materials.

In order to reduce the amount and content of synthetic polymers as much as possible, our laboratory uses natural fibers, natural nanofibers, and polysaccharide materials extracted from plants and seaweeds to create fibers and thin films, and studies their various properties. In addition, we are evaluating the effects of external factors such as light and heat on the surface and internal structure of natural polymer thin films, with the aim of creating novel nanocomposite materials.

【Related Papers】

1."Development of Glossy and UV-Resistant Urushi Coatings by Thermal Polymerization", Chieko Narita, Kazushi Yamada*, Progress in Organic Coatings, 186 (2024) 108032. (https://doi.org/10.1016/j.porgcoat.2023.108032)

2."Improving the lightfastness and thermal stability of black urushi (oriental lacquer) by kraft lignin oleate", Takao Tsuchiya, Chieko Narita, Kazushi Yamada, Adrian Moreno, Mika H. Sipponen, Hitomi Tsuda and Yoko Okahisa, Journal of Wood Science, 69, Article number 28 (2023). (https://doi.org/10.1186/s10086-023-02101-5)

3.""Characteristics of urushi film prepared through thermal polymerization", Chieko Narita, Yoko Okahisa, Saori Kitaguchi, Kazushi Yamada, Journal of Coatings Technology and Research (2023). (https://doi.org/10.1007/s11998-022-00745-4)

Please see other related papers Click.