Internet of Everything (IoE), that mounts sensors on various things and utilizes the large amount of information from the sensors with the connect to the Internet, has been attracting considerable attention as a technological innovation that will lead to the fourth industrial revolution. Especially, sensors are one of the indispensable elements that support IoT. Smart textiles, that mount sensors to textiles or clothes, have been also attracted considerable attention as the tools of wearable biological sensing because they enable to collect biological information with conventional clothing. Our laboratory is working on the development of functional polymer nano/micro fibers and their application to smart textiles.

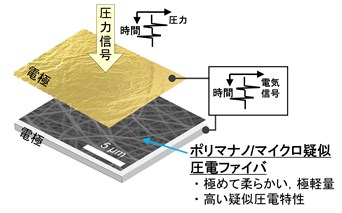

Pressure sensor and energy harvester comprised of polymer nano/micro fibers

Polymer nano/microfibers have unique characteristics such as ultra-small size, ultra-light weight, and mechanical flexibility. Furthermore, by adding electrical or optical functions, there is a possibility to create new, ultra-small, ultra-lightweight, and flexible optoelectronic devices that have never existed before in the world. Our research group is working on pressure sensors using polymer nano/microfibers. We have previously demonstrated that polystyrene, an inexpensive general-purpose polymer that does not normally exhibit piezoelectric properties in film form, can exhibit pseudo-piezoelectric properties that closely resemble the piezoelectric properties of piezoelectric materials only when it is made into nano/micro fibers using electrospinning, a world first. This finding has expanded the range of material selection for pressure sensors, and has shown the possibility of manufacturing pressure sensors that are extremely lightweight, flexible, and have excellent characteristics at low cost and over a large area by using inexpensive general-purpose polymers. In addition, since no post-processing such as poling is required, the manufacturing process is expected to be process-saving and energy-saving. In our laboratory, we are working to elucidate the science of electrospun polymer nano/microfibers that exhibit such pseudo-piezoelectric properties and to develop their applications.

[Ref]Ishii et al.“Electromechanically active as-electrospun polystyrene fiber mat: Significantly high quasistatic/dynamic electromechanical response and theoretical modeling”, Macromol. Rapid Commun. 41, 2000218 (2020)(Highlighted in Front Cover Picture).

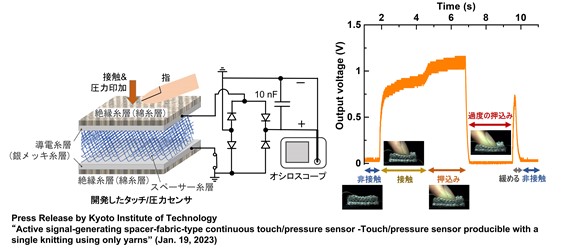

Development of active signal-generating touch/pressure sensor produced with single step knitting

With considerably growing attention for IoE, sensors are expected to benefit for various fields including medical and nursing care. Fabric-type touch/pressure sensors have high affinity for sensing people’s motion/pressure because fabrics have been used in everyday life. Our group is working on development of novel active signal-generating touch/pressure sensing fabrics and their applications.